ARC WELDING SERVICE CO.,LTD.

Hotline : 090-9151999

Contact Center

TEL : 0-2542-0420 FAX : 0-2542-0421

EMAIL : info@arcweldingservice.com

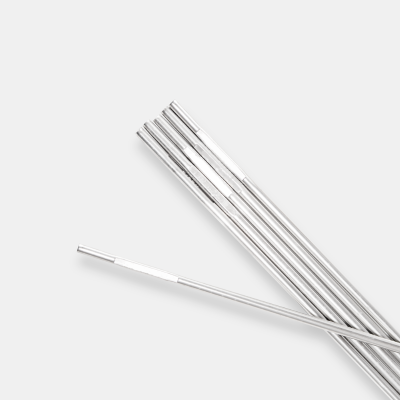

washingtonalloy

60 (ERNICU-7)

| *Ni | 62.0-69.0 |

| C | 0.15 max. |

| Mn | 4.0 max. |

| Fe | 2.5 max. |

| S | 0.015 max. |

| Si | 1.25 Max. |

| Cu | Balance |

| Al | 1.25 max. |

| Ti | 1.5-3.0 |

| P | 0.02 max. |

| Others (total) | 0.50 max. |

| Ultimate tensile strength (psi) | 70,000 |

| Yield strength (0.2% offset) (psi) | 30,000 |

| Elongation in (%) | 30 |

สินค้าใหม่

ประเภทสินค้า

บริษัท อาร์ค เวลดิ้ง เซอร์วิส จำกัด

175 ซอยลาดพร้าว 93 (โชคชัย3) ถนนลาดพร้าว แขวงคลองเจ้าคุณสิงห์ เขตวังทองหลาง กรุงเทพ 10310

โทรศัพท์ : 0-2542-0420 โทรสาร : 0-2542-0421 Hotline : 090-9151999 อีเมล์ : info@arcweldingservice.com Design by MAYAVADEE